August 1, 2025

Indopyro Materials has made a very large stride toward sustainable innovation. The company has started research to convert char obtained from the recycling of End-of-Life Tyres (ELTs) into graphene oxide. The given project is aimed at the conversion of an invaluable byproduct into a high-value nanomaterial that may be used in several industries.

Every year, millions of tires reach their end-of-life point. The pyrolysis technology aids in recycling these tires and reclaiming products such as oil, gas, steel wire, and char. Whilst the other products are put into direct use, the char tends to be underutilized. Indopyro aims to alter this situation by transforming recovered carbon black (rCB) into graphene oxide, by using pyrolyzed tyres.

The journey starts with the collection and pre-treatment of rCB. These measures make the char ready to undergo further operations:

• Drying: Moisture is removed at controlled temperatures.

• Sieving: The particles undergo screening to make them similar in size.

• Deashing: Silica, zinc, and calcium, as well as other metals, are leached with acid.

Once the purification of the char has been done, it moves into the graphene synthesis stage.

There are a couple of ways that Indopyro is considering:

1. Modified Hummers Method:

◦ Oxidation of purified char is done with the use of oxidizing agents and acids.

◦ Exfoliation separates graphene oxide layers.

◦ The process of reduction yields the reduced graphene oxide (rGO) in an eco-friendly way, such as Vitamin C or sugar.

2. Thermal or Plasma Exfoliation:

◦ High-voltage plasma or flash heating exfoliates the carbon layers.

◦ This method uses a lower quantity of chemical waste but relies on advanced tools.

3. Electrochemical Exfoliation:

◦ rCB acts as a cathode in a mild and acidic electrolyte.

◦ The treatment in the process isolates the carbon structure into a few-layer graphene.

These strategies point at making cost-effective, adaptable, and eco-friendly graphene oxide.

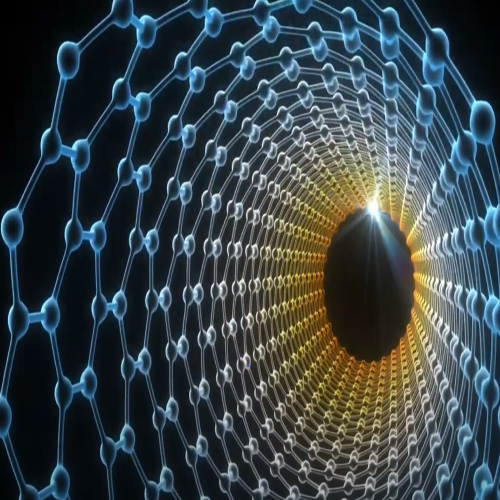

Graphene oxide is a derivative of graphene, often called the “wonder material” of the 21st century. Graphene Oxide is an extremely useful nanomaterial. It is well-recognized due to its sturdiness, its electrical conductivity, and chemical reactivity.

These highlights make it appropriate for numerous applications, including:

• Batteries and supercapacitors

• Conductive inks and coatings

• Water purification membranes

• Cement and concrete reinforcement

• Plastics and composites

• Paints, greases, and anti-corrosive materials

Producing graphene oxide from the waste tires includes a great value while lessening the impact on the environment.

Indopyro Materials has been trying to ensure that recycling is more effective. The company is showing that industrial waste can be one of the raw materials provided to leading industries through the transformation of waste tire char into the synthesis of graphene oxide. The study builds the circular economy and creates additional markets for sustainable products.

Indopyro is collaborating with a few of the best colleges and material science labs. The objective is to improve the process and guarantee steady quality for large-scale production. If effective, the project will also give a reliable supply of high-quality graphene oxide in businesses all over the world.

Indopyro Materials is changing the concept of tire recycling. Their research on converting tyre-derived char into graphene oxide has the potential to turn waste into an energy source. This innovation promotes sustainability and moves materials science forward at the international level.