August 1, 2025

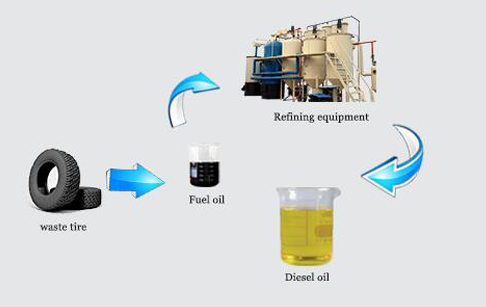

Indopyro Materials is making a huge stride in its pursuit to recycle waste into energy. It is the company that produces the Tyre Pyrolysis Oil (TPO), recovered steel wire, and char out of end-of-life tires and has even increased its research and development (R&D) processes. This revolves around improving TPO to be a more convenient diesel substitute, producing cleaner sources of fuel that, in turn, minimize environmental waste.

Considerable environmental problems are associated with waste tires; however, there is also hidden potential in them. Indopyro Materials is taking a step towards a circular economy by converting TPO into a diesel alternative. This will result in less waste in landfills, decreased reliance on crude oil, and the generation of low-cost fuel for various industries.

TPO contains a wide range of hydrocarbons, and this makes it incapable of direct application in engines. Fractional distillation is the solution provided by Indopyro. This is done through controlled heating, where the oil is separated into components on the basis of the boiling points, improving the usability and safety of the oil.

Key fractions obtained:

• Light hydrocarbons: Naphtha/gasoline range

• Middle distillates: Diesel range (C10–C20)

• Heavy oil/residue: For further refining or industrial use

The diesel cut is the most valuable portion, which is retrieved within 200°C and 350°C. This middle distillate possesses good combustion properties, hence it can be used in a wide range of applications.

There are numerous businesses and industries where TPO diesel can be utilized. It is a great substitute for conventional diesel due to its flexibility, particularly in zones where the sought-after needs are sustainability and affordability.

Current and potential uses include:

• Generators and industrial burners

• Boilers and furnaces

• Blending with conventional diesel for off-road or backup engines

• Small internal combustion engines for research purposes (after additional treatment)

The apps assist industries in cutting on fuel expenses as well as embracing environmentally friendly campaigns.

The refined diesel should be compatible with high standards of fuel to be used on the roads. The R&D team of Indopyro is currently undertaking the effort to achieve the BIS diesel specification IS 1460. Lower sulfur content and other impurities are one of the biggest challenges of the product, and it has been made safe and friendly to the environment.

Progressing research centers on:

• Optimizing refining forms for higher yields

• Reducing pollutions, counting sulfur and aromatics

• Improving fuel stability and performance

• Establishing strict quality assurance protocols

BIS compliance will allow expansion into commercial and governmental sectors.

Indopyro Materials is committed to escalating this innovation. The next task will be to test the improved TPO diesel in other types of engines with proven results and improvement of production for bigger amounts. Every achievement takes the company a step further towards providing a more environmentally friendly and cleaner fuel option to the market.

Indopyro Materials has made a significant advancement in energy retrieval by upgrading TPO into a diesel substitute through advanced R&D. The company is unlocking new ways of making cheap, eco-friendly fuels through fractional distillation and stringent quality control. This project not only helps solve the issue of waste tire disposal, but also helps in making better energy for the future.

Cleaner fuel. Less waste. A circular economy in action.